Industrielle Absaugtechnik | Kärcher Industrial Vacuuming GmbH

Ob flexibel oder fest installiert, für kleine oder große Mengen, flüssiges oder festes, unproblematisches oder gesundheitsgefährdendes Sauggut – mit den Kärcher Industriesaugern und Industrieentstaubern meistern Sie selbst härteste Reinigungsaufgaben im Handumdrehen.

Unser Qualitätsanspruch – made in Germany

Darauf können Sie vertrauen

Hochwertige Komponenten, umfassendes Know-how, große Wertschöpfungstiefe und fachlich geschultes Personal sorgen für die ausgesprochen hohe Qualität und enorme Langlebigkeit unserer bewährten Produkte – seit Jahrzehnten.

Wir verstehen uns als Partner an Ihrer Seite bei allen Herausforderungen der industriellen Absaugtechnik. Ihre Erfahrungen und Ihr Feedback sind für uns wertvoll, denn wir verfolgen das gleiche Ziel: Innovationen und Produkte zu entwickeln, mit denen Sie Ihre Ziele schneller und effizienter erreichen.

Die Bedingungen sind hart, unsere Sauger sind bereit

Jede Branche stellt ganz besondere Anforderungen an die richtige Reinigungslösung: Prozessintegration, Verarbeitung großer Mengen, Gefahrstoffe, enge Zeitfenster und vieles mehr. Hier sind sowohl universelle als auch spezifische Maschinen und Anlagen gefragt. Von der Metallverarbeitung über die Automobil- und Pharmaindustrie bis hin zur Lebensmittelindustrie ist Kärcher die erste Wahl im Bereich Industriesaugen:

- Flexibel mobil sowie stationär installierte Saugsysteme

- Optimal für das Saugen großer oder kleiner Mengen

- Vollständige Entfernung von festen und flüssigen Stoffen sowie großen Staubmengen

- Sicherheitsgerechtes Absaugen und Entsorgen von gesundheitsgefährdendem Sauggut

- Auf den industriellen Einsatz abgestimmte Geräte für den Dauereinsatz

Neuer Name – bewährte Qualität. Aus Ringler wird die Kärcher Industrial Vacuuming GmbH

Die Ringler GmbH vollzieht bei den Industriesaugern eine vollumfassende Markenumstellung. Künftig wird das gesamte Produktportfolio unter dem Markennamen Kärcher auftreten. Unsere Produkte werden standardmäßig in der neuen Corporate Farbe anthrazit ausgeliefert (sofern kein spezieller Kundenwunsch vorliegt). Mit dieser Initiative verstärkt Kärcher das einheitliche Erscheinungsbild sämtlicher Produkte der Unternehmensgruppe sowie die strategische Ausrichtung auf Sie als Kunde.

Ihr Vorteil: Sie profitieren künftig noch stärker von einem harmonisierten Produktportfolio mit einer international starken Marke – Kärcher.

Die Kärcher Industrial Vacuuming GmbH ist auch in Zeiten der COVID-19-Pandemie für Sie da.

Der Kärcher Industrial Vacuuming Produktservice im Überblick:

- Standardgeräte sind ab Lager sofort lieferbar

- Individuelle Kundenlösungen können dank gut gefüllter Lager unverändert zügig produziert werden

- Projektangebote haben aufgrund kompletter Verfügbarkeit von Vertrieb und Projektierung keine zeitlichen Änderungen

- Die Ersatzteilversorgung ist ebenfalls durch hohe Lagerbestände gesichert

Kontaktieren Sie uns gerne unter 07195 903-0.

Montag bis Freitag von 7 – 20 Uhr und samstags von 8 – 16 Uhr

Um unsere Kunden, Lieferanten und uns selbst zu schützen, haben wir selbstverständlich die Hygiene- und Sicherheitsmaßnahmen in unserem Hause angepasst. Dabei haben wir uns an den Vorgaben der WHO sowie dem Robert-Koch-Institut orientiert.

Mit freundlichen Grüßen

Ihr Kärcher-Team

Der Professional Produktberater für unsere Industrielle Absaugtechnik

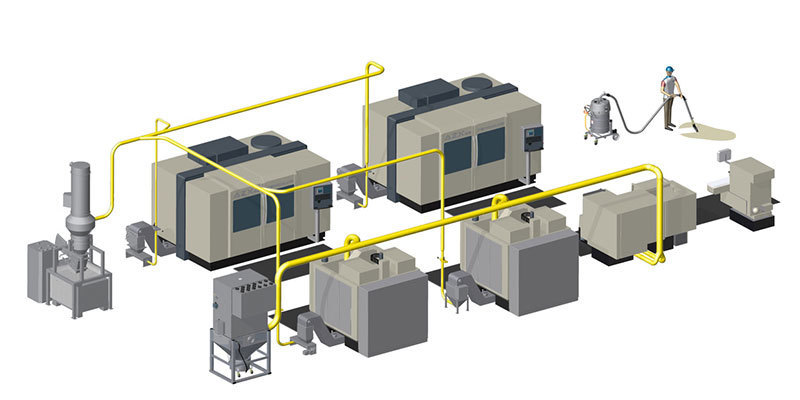

Ein System, das den Unterschied macht: Wir bietet Industrielle Absaugtechnik in allen Varianten – vom mobilen Gerät bis zur schlüsselfertigen Absaug- oder Entstaubungsanlage.

Vielfältige Technik blitzschnell finden: der Kärcher Produktberater

Wir zeigen Ihnen im Handumdrehen genau das Kärcher Professional Gerät, das optimal zu Ihrer konkreten Reinigungsaufgabe passt.

Über 50 Jahre Kompetenz

Mit dem Kärcher Industriesaugsystem profitieren Sie von über 50 Jahren Erfahrung. Wir stehen in ständigem Kontakt zu unseren Kunden weltweit, um gemeinsam bestehende und neue Aufgabenstellungen zu analysieren und unsere Produkte optimal darauf abzustimmen.

IHRE BRANCHE – UNSER SAUGER. DIE KÄRCHER SAUGSYSTEME BEWÄHREN SICH IN DEN UNTERSCHIEDLICHSTEN BEREICHEN UND ZIELGRUPPEN. TAG FÜR TAG.

IHR SCHMUTZ IST UNSER PROBLEM. KÄRCHER BIETET FÜR JEDE ANWENDUNG DIE PASSENDE GERÄTEKLASSE.

Für jedes Problem die richtige Lösung

Unsere Kärcher Industriesauger und Industrieentstauber bieten Ihnen Lösungen für jede industrielle Absaugaufgabe: flexibel mobil oder stationär installiert, zum Absaugen grober Späne bis zu feinsten schwebenden Partikeln, für kleine oder große Mengen, für flüssiges oder festes, unproblematisches oder gesundheitsgefährdendes Material.

Industriesauger

Industriesauger sind für das stationäre oder mobile Aufsaugen von trockenen sowie nassen Spänen, grobem Staub und ähnlichen, sich absetzenden Partikeln konstruiert. Dafür arbeiten Industriesauger mit hohem Unterdruck bei relativ niedrigem Luftvolumenstrom.

Industrieentstauber

Entstauber sind stationäre Geräte, die schwebende Partikel wie Staub und feinste Späne aus der Luft absaugen. Dafür arbeiten Industrieentstauber mit niedrigem Unterdruck bei relativ hohem Luftvolumenstrom.

INDUSTRIESAUGER FÜR FLÜSSIGKEITEN / SPÄNE

INDUSTRIESAUGER FÜR GROSSE MENGEN ABRASIVER SPÄNE UND SCHMIERSTOFFE

In der Industrie werden Sauger gebraucht, die mehrere Stunden täglich oder im Dauerbetrieb 24/7 souverän durchhalten. Das Spektrum an Stoffen reicht dabei von kleinen bis zu sehr großen Mengen abrasiver Späne und grober Partikel über abgesetzte Medien bis zu Flüssigkeiten wie Öl, Kühlemulsion und Wasser.

INDUSTRIESAUGER FÜR FESTSTOFFE / STÄUBE

DIE SAUGER MIT DER BESONDEREN FILTERTECHNIK

In den verschiedenen Industrien müssen die unterschiedlichsten Stoffe und Medien gesaugt werden. Dabei stellen abgesetzte Medien, gesundheitsschädliche Stäube, feine und grobe Späne, Sand, Strahlmittel, Faserstoffe aller Art, Nahrungsmittelreste, organische Substanzen, sehr leichte bis sehr schwere Materialien höchste Anforderungen an die eingesetzte Filtertechnik. In unserem Kärcher Industriesystem finden Sie den optimalen Filter für jede Aufgabe, egal ob täglich stundenweise oder im Dauerbetrieb 24/7 direkt im Prozess.

INDUSTRIESAUGER EX

GEPRÜFTE SICHERHEIT FÜR DEN EX-GEFÄHRDETEN BEREICH

Das Saugen in explosionsgefährdeten Bereichen stellt höchste Ansprüche an die Gerätequalität. Industrielle Kärcher Ex-Sauger erfüllen diese Normen und sind zum Teil richtlinienkonform zertifiziert durch den TÜV Süd und IBExU.

INDUSTRIEENTSTAUBER

FÜR DIE EFFEKTIVE ERFASSUNG SCHWEBENDER PARTIKEL

Schwebende Partikel können sehr verschieden sein: Feinstaub, gesundheitsschädlicher Staub, feine Späne und Abrieb aller Art. In vielen Industrien ist das kontinuierliche Absaugen der Prozessstäube von Metallen, Glas, Stein, Textilfasern, Agrarprodukten oder Chemikalien unmittelbar im Prozess unverzichtbar. Unsere Industrieentstauber erfassen im Dauerbetrieb 24/7 direkt an Bearbeitungs- bzw. Abfüllanlagen angeschlossen zuverlässig schwebende Partikel selbst in großer Menge.

INDUSTRIEENTSTAUBER EX

FÜR ALLES, WAS SCHWEBT UND EX-GEFÄHRLICH IST

Die kontinuierliche Absaugung schwebender, explosiver Partikel direkt an der Entstehungsquelle im Prozess stellt höchste Anforderungen an Industrieentstauber. Unsere Entstauber und Entstauber Ex bewähren sich seit vielen Jahren im stationären Dauereinsatz 24/7 in vielen Bereichen der Industrie, insbesondere in der Metall- und Holzbearbeitung, in Automotive, Chemie und Pharma, Lebensmittel, Papierherstellung, in der gummi- und kunststoffverarbeitenden Industrie sowie in der Zone 22.

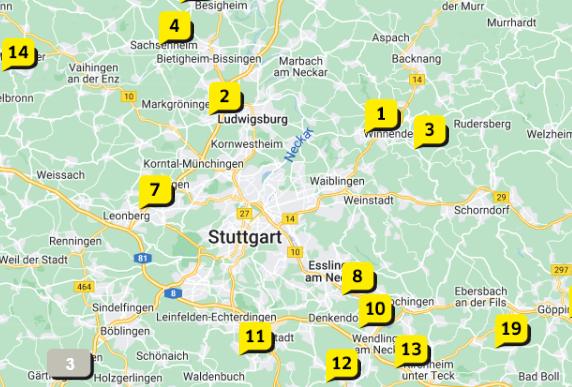

FINDEN SIE IHREN HÄNDLER IN IHRER NÄHE

Kärcher vor Ort - für Sie und Ihre Aufgaben.

Unsere Fachhandelspartner beraten Sie gerne persönlich und kompetent. Tauchen Sie ein in die Welt von Kärcher und lassen Sie sich begeistern.

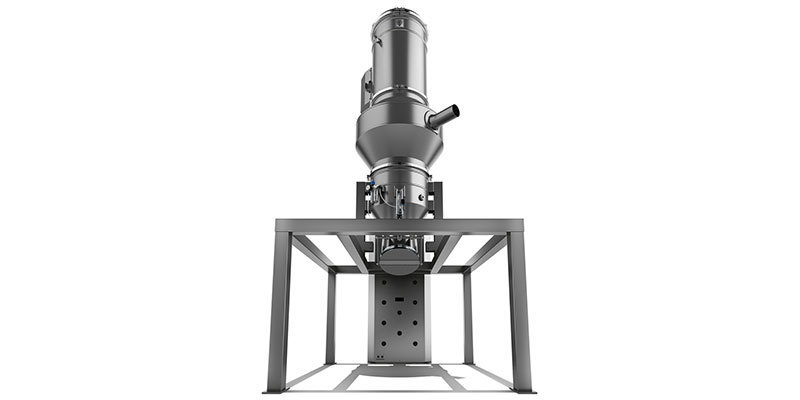

Kundenspezifische Lösungen für spezielle Aufgaben

Individuell gelöst

Die Anforderungen an Absaugsysteme in der Industrie können sehr spezifisch sein. Wir projektieren jede Anlage individuell auf Ihre spezifischen Bedürfnisse hin. Unser Leistungsspektrum reicht von der einfachen mobilen Lösung bis hin zu hochkomplexen, spezifisch angepassten und fest verrohrten Absauglösungen. Mit mehr als 50 Jahren Erfahrung in der Entwicklung und Realisierung industrieller Saugsysteme sind wir Ihr kompetenter Partner. Dadurch bekommen Sie effiziente Komplettlösungen aus einer Hand.

Rohrleitungen - Leistung perfekt angebunden.

Unsere stationären Industriesauger können Sie als Ein- oder Mehrplatzsysteme mit Handabsaugstellen oder direkt in den Prozess integriert einsetzen. Dafür bieten wir Ihnen alle benötigten Komponenten, von den Saugstellen und Zubehören bis zu individuell angepassten Rohrleitungen.

SERVICE

Auf uns können Sie sich verlassen. Auch nach Abnahme der Anlage bieten wir Ihnen einen Rundumservice. Erfahren Sie mehr über unsere Angebote und nehmen Sie mit uns Kontakt auf.

REFERENZEN

Darauf können wir stolz sein: Unsere Anlagen stehen bei zahlreichen namhaften Unternehmen auf der ganzen Welt. Ob fertige Produkte oder individuell angepasst – wir bieten für jeden Kunden die passende Lösung vor Ort.

ÜBER UNS

Unsere DNA

Wer wir sind: Der Experte für industrielle Sauglösungen.

Mit über 50 Jahre Erfahrung in der Branche treffen sie bei uns die Experten. Unser professionelles Team stellt gemeinsam mit ihnen ihre perfekt auf sie zugeschnittene Lösungen aus dem vielfältigen Produktportfolio zusammen und berät sie umfassend. Unser Antrieb ist es hierbei unseren Kunden zu einer sauberen, sicheren Arbeitsumgebung durch effiziente Reinigungslösungen zu verhelfen.

Was wir bieten: Qualitativ hochwertige Lösungen auf die sie vertrauen können.

Mit unseren Lösungen bestehend aus hochwertigen Industriesaugern mit vielfältigem Zubehör für verschiedenste Anwendungen erleichtern wir den Alltag in Ihrer Produktion.Ergänzt werden unsere Lösungen durch Servicekonzepte, damit ihre Industriesaugerlösung allzeit bereit ist. Zu jedem Zeitpunkt stehen wir ihnen hierbei mit Rat und Tat zur Seite. Darauf können sie vertrauen.

Wer dahinter steht: Mit zwei Herzen in einer Brust stehen wir für die Jahrzehnte langen Erfolge der Ringler GmbH und die Veränderung zur Kärcher Industrial Vacuuming GmbH.

Hochwertige Komponenten, umfassendes Know-how, große Wertschöpfungstiefe und unsere Experten sorgen für die ausgesprochen hohe Qualität und enorme Langlebigkeit unserer bewährten Lösungen – seit Jahrzehnten. Mit gebündelter Expertise in Entwicklung, Produktion, Vertrieb, Service und Anwendungstechnik leisten wir den Beitrag zu ihrer saubereren, sichereren und umweltfreundlicheren Produktion.

SCHWEIßEN

Die hohe Wertschöpfungstiefe ermöglicht es uns, flexibel auf Ihre Wünsche zu reagieren.

LACKIEREN

Gerne liefern wir unsere Saugsysteme nach Ihrer Farbvorstellung.

MONTIEREN

Made in Germany – optimal strukturierte Arbeitsabläufe sichern höchste Qualitätsstandards.

Kostenloses E-Book zur Absaugtechnik in der Industrie!

In unserem kostenlosen E-Book erfahren Sie mehr zur Nutzung von speziellen Saugern für die Industrie.

Sie sind in der Metallverarbeitung oder Lebensmittelfertigung tätig und interessieren sich für die Vorteile von Industriesaugern für Ihre Anwendung? Dann helfen wir Ihnen in unserem E-Book weiter. Erhalten Sie branchenspezifische Tipps und zusätzliche Informationen zur Prozessüberwachung für optimale und effiziente Arbeitsergebnisse der Industriesauger.

INDUSTRIEREINIGUNG REFERENZEN

Werterhalt rauf, Produktionsstillstand runter

Manchmal braucht es Impulse von außen, um weiter wachsen zu können. Als Ihr Partner in Sachen Reinigung möchten wir Ihnen stets die richtigen Denkanstöße liefern – denn optimierte Prozesse können die Effizienz steigern und Ausfallzeiten deutlich reduzieren.

Kärcher betreut unzählige Kunden in der Industrie quer durch verschiedenste Branchen und bietet für jede Anforderung die ideale Lösung.

Wir sind mit einigen unserer Kunden, wie beispielsweise BMW, Bitburger und Nestlé, in intensive Gespräche gegangen und haben die spannenden Einblicke für Sie zusammengetragen. Neugierig geworden?

Sie haben Ihren Sauger gefunden?

Kärcher Professional Industriesauger erhalten Sie bei allen Kärcher Fachhändlern und direkt bei Kärcher. Finden Sie Ihren passenden Händler über unsere Händlersuche oder nehmen Sie direkt Kontakt mit uns auf.

Kontakt

Beratung von Profis für Profis

Nehmen Sie jetzt Kontakt mit uns auf und wir beraten Sie gerne kostenlos und unverbindlich.

Händlersuche

Mit der einfachen Händlersuche finden Sie schnell und bequem einen Händler auch in Ihrer Nähe.

Newsletter

Mit dem Kärcher Newsletter erhalten Sie regelmäßig alle Neuigkeiten zu Produkten, Services und Aktionen aus der Welt von Kärcher Deutschland.